Metal Additive Manufacturing Laser Cladding DED Process: The Magical Metal “Repairer” and “Creator”

In today’s era of rapid technological advancement, metal additive manufacturing technology is gradually entering the public eye, among which the laser cladding direct energy deposition (Directed Energy Deposition, abbreviated as DED) process is particularly attracting attention. It is like a magical metal “repairer” and “creator”, playing a unique role in the field of industrial manufacturing. Now, let’s unveil its mysterious veil together.

What is the Laser Cladding DED Process?

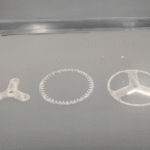

Simply put, the laser cladding DED process is an additive manufacturing technology that uses a high-energy laser beam as a heat source to melt and deposit metal powder or wire on the surface of a substrate material, creating or repairing metal parts through layer-by-layer accumulation. To put it another way, it is like “3D printing” with metal materials, except that this “printer” uses a laser and the “ink” is metal powder or wire.

The Working Principle of the Laser Cladding DED Process

Imagine a precise nozzle that can spray metal powder while a high-energy laser beam shines on the powder. When the laser hits the metal powder, the powder quickly absorbs the laser’s energy, and its temperature rises sharply, instantly changing from solid to liquid. At the same time, the nozzle moves along a pre-set path, accurately depositing the molten metal droplets on the substrate material. These liquid metals quickly cool and solidify upon contact with the substrate, firmly bonding with it. As the nozzle continuously moves and metal powder is continuously supplied, layer upon layer of metal is built up, eventually forming the three-dimensional metal parts we need.

The Advantages of the Laser Cladding DED Process

Strong Repairing Capacity

In industrial production, many expensive metal parts may become unusable due to wear, corrosion, or accidental damage. If new parts are directly replaced, the cost would be very high. However, the laser cladding DED process can come to the rescue. It can precisely cladding a new layer of metal material on the surface of damaged parts, repairing the damaged areas and restoring their original shape and performance, significantly reducing production costs. For example, in the repair of aircraft engine blades, the laser cladding DED process can restore the worn blade surface to be as good as new, allowing the blade to continue functioning.

Flexible Material Selection

This process can use various types of metal materials, including stainless steel, titanium alloys, aluminum alloys, etc. Moreover, different metal powders can be mixed during the cladding process to obtain composite materials with special properties. This is like a chef flexibly combining various ingredients according to different recipes to create delicious dishes. By flexibly choosing materials, we can manufacture metal parts with different performance requirements such as high strength, high hardness, and corrosion resistance, meeting various complex industrial application needs.

High Manufacturing Efficiency

Compared to traditional processing methods, the laser cladding DED process has a faster manufacturing speed. It can directly manufacture based on 3D models without complex molds and processing procedures. In projects with high production cycle requirements, this process can quickly manufacture the required parts, significantly shortening the product’s research and development and production time. For example, in the manufacturing of customized mechanical parts, the laser cladding DED process can complete the entire process from design to manufacturing within a few days, while traditional methods may take weeks or even months.

Application Fields of the Laser Cladding DED Process

Aerospace parts usually have extremely high requirements for material performance and precision. The laser cladding DED process can produce complex-shaped and high-performance components such as aero-engine blades and wing structural parts. At the same time, it can also repair damaged aviation parts, extend the service life of parts, and reduce the maintenance costs of aerospace equipment.

In the automotive manufacturing field, the laser cladding DED process can be used to manufacture high-performance key parts such as engine blocks and crankshafts, improving the strength and wear resistance of parts. In addition, it can also repair and strengthen automotive molds, extend the service life of molds, and reduce the cost of automotive production.

In the energy field, many components of equipment in the oil and gas extraction and power industries need to withstand harsh environments such as high temperatures, high pressures, and corrosion. The laser cladding DED process can clad a layer of metal materials with special properties on the surface of these components, improving their corrosion resistance, wear resistance, and high-temperature resistance, and ensuring the safe and stable operation of energy equipment.

Although the laser cladding DED process has many advantages, it currently faces some challenges, such as high equipment costs and the difficulty of quality control during the cladding process. However, with the continuous progress of technology, it is believed that these problems will be gradually solved. In the future, the laser cladding DED process is expected to be widely applied in more fields, bringing more surprises and changes to our industrial manufacturing.

By vidalin.912@gmail.com

October 21, 2025Enjoyed looking through this, very good stuff, thanks.

By vidalin.912@gmail.com

October 27, 2025Thanks, We’re glad you like what we share:)

By vidalin.912@gmail.com

November 2, 2025Nice read, I just passed this onto a friend who was doing some research on that. And he just bought me lunch as I found it for him smile So let me rephrase that: Thank you for lunch!

By vidalin.912@gmail.com

November 6, 2025Haha, you’re welcome! I’m glad my article provided you with a lunch!