Copper alloys: Metal materials with wide applications

In the world of metals, copper alloys are a very important and widely used type of material. Copper alloys, simply put, are alloys formed by adding other elements to copper as the base. Why add other elements? This is because although pure copper has many advantages, such as good electrical and thermal conductivity and a relatively attractive appearance, its strength and hardness and other properties cannot meet the requirements in some cases. By adding other elements, copper alloys can have more outstanding comprehensive performance.

Common copper alloys include brass, bronze and white copper. Brass is an alloy of copper and zinc. It usually has a golden yellow color and looks very beautiful. Brass has good plasticity and corrosion resistance, and is easy to process. Therefore, it can be seen in many fields. Many decorative items, door locks, pipe fittings, etc. are made of brass. Because it is both beautiful and durable, it can meet the dual needs of daily use and decoration.

Bronze is an alloy of copper and tin, among other elements. It has a long history and was widely used in ancient times to make various utensils and weapons. Bronze has relatively high strength and hardness, and its chemical properties are also relatively stable. Nowadays, bronze is often used to manufacture parts for precision instruments, bearings, etc., and plays an important role in industrial production.

The picture was generated by AI

White copper is an alloy of copper and nickel. It has a silvery-white appearance with a metallic luster. White copper has strong corrosion resistance, especially in harsh environments such as marine environments. Therefore, it is often used to manufacture parts for ships, seawater desalination equipment, and so on.

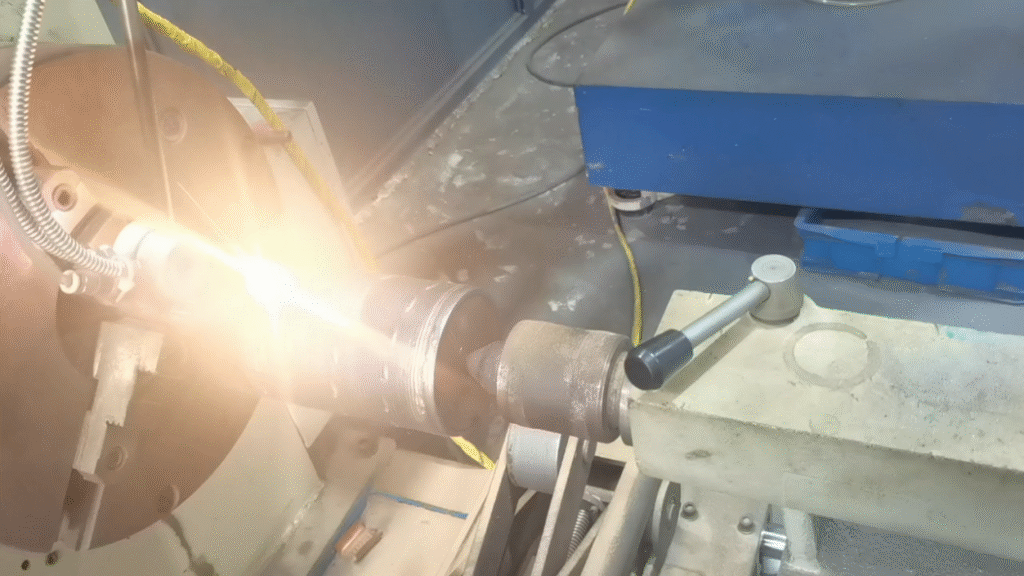

Now let’s talk about the additive manufacturing of copper alloys, which is an extremely cool technology. Traditionally, metal parts are manufactured through methods such as casting, forging, and mechanical processing. Some of these methods have complex processes and cause significant material waste. Additive manufacturing, simply put, is about “adding”. It creates parts by layering materials based on three-dimensional model data.

In the additive manufacturing of copper alloys, commonly used techniques include laser powder bed fusion and laser directed energy deposition. Laser powder bed fusion technology is like a super-precise “3D printer”. It first spreads a very thin layer of copper alloy powder on the worktable, then a laser scans along the designed path, melting and solidifying the powder together. After one layer is completed, a new layer of powder is spread, and this process is repeated until the part is manufactured. This method can produce copper alloy parts with very complex shapes and high precision, and has great application potential in aerospace, electronics, and other fields.

Laser directed energy deposition technology feeds copper alloy powder while using a laser to melt the powder and form it into shape. It is like a “construction expert” that can move freely, capable of repairing and remanufacturing parts, as well as directly manufacturing large copper alloy parts.

Copper alloy additive manufacturing technology enables us to produce complex-structured parts that are difficult to achieve through traditional methods, saves materials and time, and improves production efficiency. With the continuous development of the technology, it is believed that copper alloy and its additive manufacturing technology will shine in more fields and bring more surprises to our lives.

By vidalin.912@gmail.com

October 22, 2025Ne’er knew this, appreciate it for letting me know.

By vidalin.912@gmail.com

October 27, 2025Thank you for your browsing, we will continue to share more “interesting knowledge”:)