The Secrets of Metal Powder Morphology: Sphericity, Satellites, and Hollow Powder

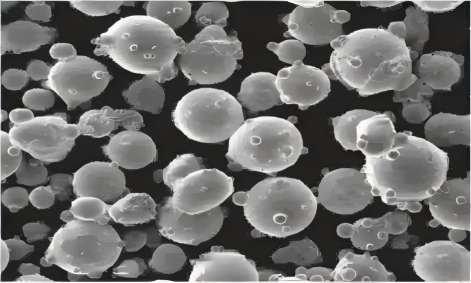

In advanced manufacturing fields such as metal additive manufacturing (3D printing), powder metallurgy, and injection molding, the morphology of metal powder is critically important—it directly influences powder flowability, packing density, the final product’s density, and mechanical properties. Among these, sphericity, satellite powder, and hollow powder are three core evaluation metrics.

Sphericity

Definition: Sphericity refers to how closely an individual powder particle resembles a perfect sphere. It quantifies the roundness of a particle’s contour, with a perfect sphere having a sphericity value of 1. Lower values indicate more irregular shapes (e.g., ellipsoidal, flaky, or dendritic).

Impact on Powder Performance:

Flowability: High-sphericity powders flow exceptionally well—like tiny ball bearings—spreading smoothly and uniformly on the print bed. This ensures printing precision, consistent layer thickness, and fewer defects.

Packing Density: Spherical particles achieve the densest possible packing, increasing green body density, reducing sintering shrinkage, and ultimately yielding a more compact, stronger final product.

Printing Stability: Good flowability enables uniform and reliable powder feeding, enhancing process stability and repeatability.

Satellite Powder

Definition: Satellite powder forms during production (e.g., gas atomization) when small molten droplets collide with and adhere to the surface of larger, already solidified or semi-solidified particles before they fully cool. Imagine tiny “satellites” stuck to a larger “planet” particle.

Impact on Powder Performance:

Reduced Flowability: The irregular surface caused by satellite structures increases friction between particles, significantly hindering smooth powder flow and leading to uneven spreading.

Defect Introduction: During printing and melting, satellite powder may not fully melt or can form irregular molten pools, creating micro-cracks or lack-of-fusion defects that compromise mechanical properties (especially fatigue strength).

Packing Density: The irregular shapes lower the powder’s loose packing density.

Process Indicator: Satellite content serves as a key metric for evaluating the stability of gas atomization and other production processes, as well as overall powder quality.

Hollow Powder

Definition: Hollow powder contains enclosed pores or cavities within the particle. These form during gas atomization when gases trapped inside molten droplets fail to escape before solidification.

Impact on Powder Performance:

Densification Challenges: During printing or sintering, the trapped gas inside hollow powder expands or struggles to escape, often leaving pores in the final product. This severely reduces material density and mechanical properties (strength, toughness, fatigue life).

Potential Contamination Source: If the inner cavity walls contain incompletely solidified melt or impurities, they may act as contamination sources.

Density Anomalies: Hollow powder has lower density than solid powder of the same composition, potentially causing errors in density-based sorting or detection.

Process Sensitivity: Its presence reflects how process parameters (e.g., superheat, gas pressure, nozzle design) affect the internal quality of the powder.

Summary: The Hidden Power of “Morphology”

Metrics like loose packing density and tapped density may seem like simple measurements, but they encapsulate a wealth of information about metal powder—flowability, particle shape, size distribution, and compressibility potential.

High Sphericity is the foundation for excellent flowability and high packing density, making it the top priority for high-quality metal powder.

Satellite Powder disrupts flowability and undermines the final product’s density and performance, requiring strict control of its content.

Hollow Powder is the “enemy” of internal densification, directly introducing hard-to-eliminate pore defects.

In the production and application of high-end metal powder, precise measurement and control of sphericity, satellite content, and hollow powder rate are indispensable quality assurance steps. These ensure not only smooth powder processing (e.g., uniform spreading) but also the achievement of desired high performance in the final product (e.g., high strength, density, and longevity).

These seemingly microscopic “morphological” features are, in fact, the critical keys to the success or failure of macroscopic products.