The Secret of Metal Powder’s “Size”: Particle Size Distribution and Its Significance

In the microscopic world of metal powder, particles aren’t all identical—they vary in size, much like grains of sand on a beach. Particle size distribution (PSD) is the key metric that describes the proportion of different-sized particles within a powder batch. It acts as a precise “ruler,” defining the collective profile of powder particles.

Definition: A “Family Portrait” of Particle Sizes

Particle Size : Refers to the dimensions of a single powder particle, commonly expressed as an equivalent diameter (e.g., volume-equivalent or projected-area equivalent diameter), with units typically in micrometers (μm).

Particle Size Distribution : Describes the mass percentage or number percentage of particles within specific size ranges (e.g., from 1μm to 100μm) across the entire powder sample. It is typically illustrated through charts (e.g., histograms, cumulative distribution curves) or key parameters.

Key Parameters:

D10, D50, D90: These represent the particle size values at which 10%, 50%, and 90% of the powder particles are smaller, respectively.

D50 (Median Diameter): The most representative value—meaning ~50% of particles are smaller, and ~50% are larger.

Span/Distribution Width: Calculated as (D90 – D10) / D50. A smaller span indicates a more concentrated, uniform particle size distribution; a larger span suggests a wider range of sizes.

Significance: The Performance Code That Touches Everything

Particle size distribution is far more than a simple size description—it profoundly influences every aspect of metal powder performance, from processing to the final product.

1. Flowability & Packing Efficiency

Critical Impact: Particle size directly affects powder flowability. Extremely fine powders (e.g., those with >50% particles <10μm) are prone to static buildup and agglomeration, leading to poor flow—resulting in difficulties in powder spreading (e.g., clogging during 3D printing) or uneven feeding. Spherical powders with medium sizes and concentrated distributions typically exhibit the best flowability.

Packing Density: Ideally, a mix of particle sizes (broad distribution or specific grading) allows smaller particles to fill gaps between larger ones, significantly boosting apparent and tap densities. This lays a solid foundation for subsequent densification. However, overly wide distributions may cause fine particles to coat larger ones or separate, which is counterproductive.

2. Printing/Forming Process Performance

Powder Bed Quality (3D Printing): Uniformly distributed, well-flowing powders form thinner, more even, and denser layers—essential for ensuring print precision and minimizing defects like balling or warping.

Sintering Behavior: Fine powders have higher specific surface areas and greater sintering activity, promoting densification but potentially causing excessive shrinkage or deformation. Coarse powders sinter more slowly, making densification harder. An optimal distribution balances sintering speed and dimensional stability.

Compaction Performance (Powder Metallurgy): Fine powders are easier to compact but harder to eject from molds; coarse powders flow better but compress less effectively. The distribution must be optimized for specific pressing processes.

3. Final Product Performance

Density: Particle size distribution directly impacts initial powder packing density (apparent/tap density), which in turn affects the final product’s density after sintering or printing. High density is the foundation for achieving strength, toughness, and fatigue resistance.

Surface Quality: Powders with finer particles (especially those with a smaller D90) often yield smoother surface finishes (e.g., in 3D-printed parts).

Microstructure & Property Uniformity: Uniformly distributed powders help form more consistent microstructures (e.g., grain size, pore distribution), reducing performance variations.

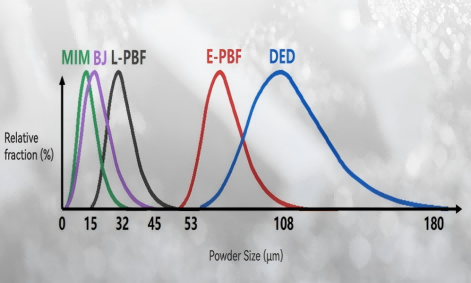

Cost & Utilization: Specific applications (e.g., powder bed 3D printing) require powders within strict size ranges (e.g., 15–53μm). Powders concentrated in these ranges have higher utilization rates and less waste. Broad distributions mean some powder must be sieved out, increasing costs.

Summary: The “Golden Ratio” of the Powder World

Particle size distribution is one of the most critical physical properties of metal powder. Like an invisible blueprint, it predefines how powder will behave during flow, packing, forming, and sintering—and ultimately reflects in product quality and performance.

Whether the goal is achieving extreme 3D printing precision or ensuring stable strength in powder metallurgy parts, precisely controlling and optimizing particle size distribution (e.g., targeting narrow distributions, specific D50 values, or reasonable D10/D90 ranges) is the essential path to unlocking material potential and enabling high-performance manufacturing.

Understanding this “ruler” means mastering the key formula for tailoring powder performance.