The Science of Powder Packing: How Metal Powders “Stack Up” Matters

In the world of metal powder processing—whether for 3D printing, powder metallurgy, or injection molding—how powder “piles up” directly impacts the success of subsequent processes and the performance of the final product. Apparent density (bulk density) and tap density are the two key metrics that evaluate this “stacking” ability.

Apparent Density

Definition: Apparent density refers to the mass per unit volume of metal powder when it naturally fills a fixed container under its own weight (with no external force applied). In simple terms, it’s the density of powder when it’s “loosely piled” together. It’s typically measured in grams per cubic centimeter (g/cm³).

Why It Matters:

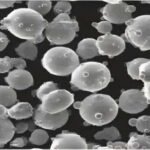

Linked to Flowability: Powders with good flowability (e.g., high sphericity, fewer satellite particles) have less friction between particles, allowing them to fill gaps more smoothly. These powders usually have higher apparent density. It serves as an indirect but quick indicator of flowability.

Critical for Initial Processes: In mold filling or 3D printing powder deposition, apparent density determines the initial density and uniformity of the powder layer. It’s a foundational parameter for calculating powder loading and predicting sintering shrinkage.

Red Flags for Issues: Abnormal apparent density may signal problems like irregular particle shapes, excessive satellite particles, severe agglomeration, or overly fine powder.

Tap Density

Definition: Tap density is the maximum mass per unit volume of metal powder achieved when it’s compacted in a fixed container after being subjected to specific vibrations (with controlled frequency and amplitude). It represents the “tightest possible” packing density achievable with external vibration. Like apparent density, it’s also measured in g/cm³.

Why It Matters:

Reveals Compressibility: Tap density shows how well powder particles can rearrange, reduce voids, and achieve denser packing under vibration. It directly reflects the powder’s compressibility.

Predicts Final Density: The closer tap density is to the theoretical density of the material, the more tightly the powder is initially packed. This makes it easier to achieve high final density after sintering, with smaller and more controllable shrinkage—crucial for manufacturing high-precision, high-performance parts.

Particle Shape & Size Matter: Powders with good sphericity and well-optimized particle size distribution (where smaller particles efficiently fill gaps between larger ones) typically have a much higher tap density than apparent density, and both values are relatively high. The opposite results in a smaller gap between the two.

Impacts Handling: Tap density determines how much powder can be compacted during transport and storage, influencing packaging volume and cost.

The Dynamic Duo: Apparent vs. Tap Density

The ratio of tap density to apparent density—known as the Hausner ratio—is a core metric for evaluating powder flowability and compressibility:

Ratio ~1 (e.g., 1.0–1.1): Indicates excellent flowability (like water) but poor compressibility (hard to pack further).

Ratio >1.4: Suggests poor flowability but strong compressibility (density can be significantly improved through vibration or pressing).

Together, these two metrics define the full range of a powder’s state—from “loose” to “tight.”

In processes like powder pressing (e.g., powder metallurgy) or sintering, the target final density usually falls between apparent and tap density (and can exceed tap density with applied pressure). Understanding these values is essential for precisely controlling process parameters and ensuring consistent product quality.

Summary: The Foundation of Packing, the Base of Performance

Apparent density and tap density may seem like simple measurements, but they encapsulate a wealth of information about metal powder—flowability, particle shape, size distribution, and compressibility potential. They serve as:

A “Health Report” for Powder Quality: Quickly screening a powder’s suitability for specific processes.

A “Navigation Map” for Process Design: Providing key data for mold design, powder loading calculations, and shrinkage predictions.

A “Crystal Ball” for Product Performance: Tight initial packing is the foundation for achieving high-density, high-strength, and high-precision final products.

In the world of metal powder applications, mastering apparent and tap density is like unlocking the “art of stacking”—paving the way for manufacturing exceptional products.