The Flow Factor: Why Metal Powder “Fluidity” is the First Step to Success

On the stage of metal powder processing—whether for 3D printing, powder metallurgy, or injection molding—the ability of powder to flow smoothly like fine sand is the first critical determinant of process success. Flowability is the key performance metric that evaluates just how easily and consistently powder can move.

What is Flowability?

It refers to a metal powder’s ability to overcome inter-particle friction and cohesion under gravity or external force, enabling continuous, uniform movement. Simply put, it measures how smoothly, quickly, and evenly the powder “flows.” The most common measurement method is the Hall Flowmeter Test: timing how long it takes for 50 grams of standard powder to freely flow through a standardized funnel with a specific aperture (e.g., 2.5mm or 5mm). The shorter the time (measured in seconds per 50g), the better the flowability. Alternatively, the angle of repose (the slope angle of a naturally piled powder cone relative to the horizontal plane) can be used for indirect assessment—the smaller the angle, the better the flowability.

Flowability is the lifeline that runs through the entire powder processing chain, profoundly impacting efficiency, quality, and performance from powder handling to final product formation.

Why Flowability Matters: The Backbone of Process Efficiency & Stability

3D Printing Powder Deposition

Poor-flowing powder tends to clog, clump, or unevenly spread, resulting in inconsistent layer thickness. This directly harms print precision, causing defects like warping, layer misalignment, or balling—and can even halt the printing process. High-flowability powder forms thin, uniform, and dense layers, which are essential for producing high-quality, high-precision parts.

Powder Metallurgy / Injection Molding Mold Filling

Well-flowing powder can quickly, evenly, and completely fill the intricate corners of complex molds, ensuring uniform green body (unsintered compact) density. This reduces stress concentrations and the risks of post-sintering deformation or cracking. Poor flowability leads to incomplete filling, uneven density, and skyrocketing scrap rates.

Powder Feeding Stability

In processes requiring continuous, precise powder feeding (e.g., laser cladding, powder-fed 3D printing), stable flowability is key to maintaining consistent feed rates and a stable melt pool.

Product Quality & Performance Assurance

Density & Uniformity: Good flowability enables tight, uniform powder packing (high apparent/tap density). Such layers are more likely to achieve high final density and homogeneous microstructure during pressing, sintering, or melting—directly determining core mechanical properties like strength, toughness, and fatigue life.

Dimensional Accuracy & Surface Finish: Uniform powder deposition or filling ensures high part precision, minimal shrinkage deformation, and superior surface smoothness. Flowability-related layer defects will inevitably “transfer” to the final product.

Key Factors Influencing Flowability

Particle Shape: Spherical is supreme. Smooth, spherical particles (e.g., gas-atomized powder) act like tiny ball bearings, minimizing friction and delivering optimal flowability. Irregular shapes (flaky, dendritic) or satellite particles (small particles stuck to larger ones) significantly increase friction and hinder flow.

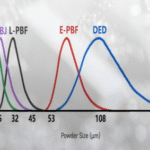

Particle Size & Distribution: Extremely fine powders (<15–20μm) tend to agglomerate due to surface adsorption, resulting in poor flowability. Medium-sized particles (e.g., 15–53μm) with a concentrated distribution typically flow better. A reasonably wide distribution (with size grading) can sometimes improve flow by allowing smaller particles to fill gaps between larger ones—but overly broad distributions may cause particle separation, which is counterproductive.

Surface Condition: Surface adsorption of moisture, gases, or oxides increases inter-particle adhesion, reducing flowability.

Material Properties: Density and hardness also play minor roles.

Flowability: The Core Bridge to Manufacturing Excellence

Metal powder flowability is the critical link between powder characteristics (shape, size) and process performance (filling, spreading), ultimately determining final product quality (density, uniformity, precision). It directly answers three key questions:

Can the process run smoothly?

Can the product be made with precision?

Can the desired performance be achieved?

In today’s pursuit of high-performance metal parts, precisely characterizing flowability (e.g., via Hall Flowmeter tests), deeply understanding its influencing factors (especially sphericity!), and rigorously selecting/optimizing powder accordingly are essential prerequisites for ensuring efficient, stable manufacturing processes and reliable, high-quality products.

Mastering the “flow” of powder is the first step toward unlocking the door to high-quality manufacturing.