Metal gas atomization: The tech magic that turns metal into “tiny metal candies”

Hello everyone! Today, let’s talk about a topic that sounds very high-tech but has a really interesting principle – metal gas atomization. Imagine if you could turn a piece of metal into a pile of tiny “metal candies”. That’s the magic of gas atomization! Now, let’s use the simplest language to reveal its secrets.

- What is metal gas atomization?

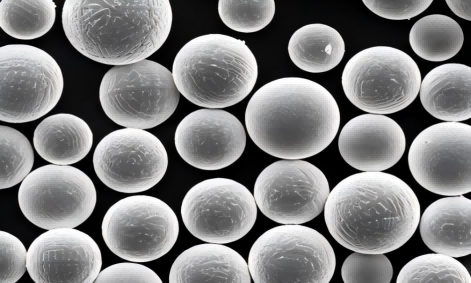

In simple terms, gas atomization is the process of using high-speed gas flow to “blow” molten metal liquid into countless small droplets, which are then rapidly cooled to form fine metal powder. This process is similar to using a hair dryer to blow melted chocolate into small particles and instantly freeze them. The diameter of these metal powders is usually finer than a human hair (about 15-150 microns), and their shape is close to small spheres, making them highly suitable for 3D printing, manufacturing high-end parts, etc.

2. The principle of gas atomization: The “shock battle” of high-pressure gas

The core principle of gas atomization can be understood in three steps:

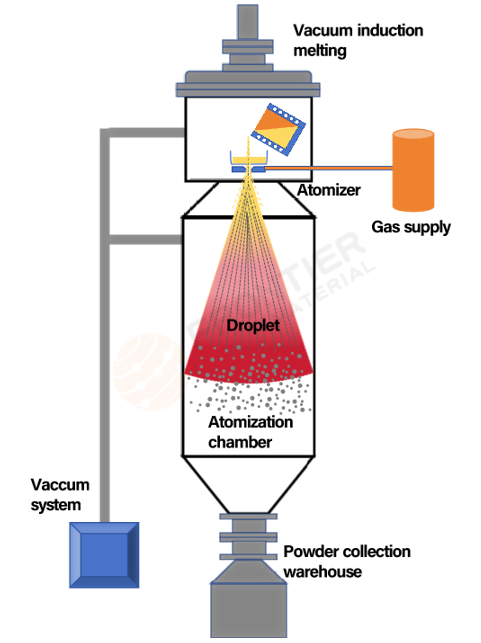

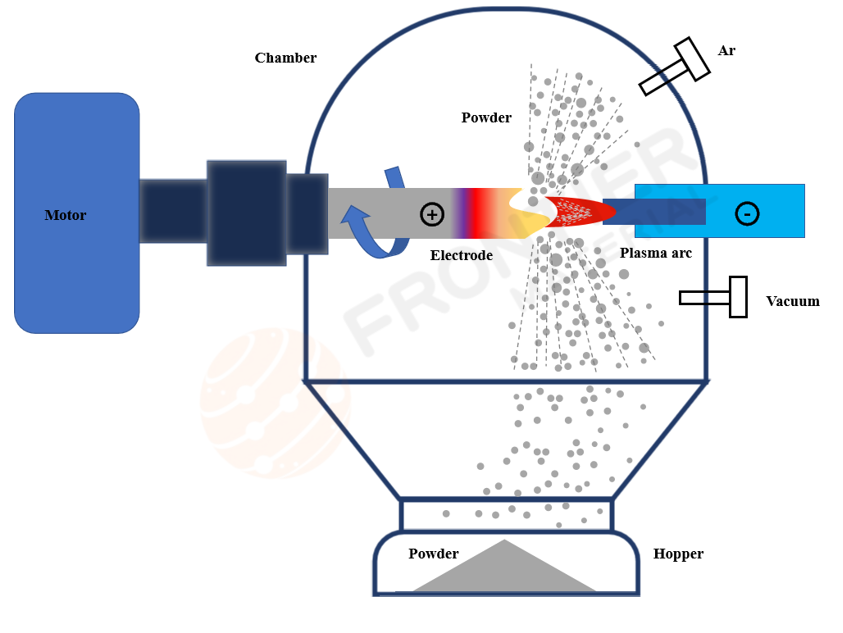

Melting metal: Put the metal block into a high-temperature furnace and heat it until it completely turns into liquid (just like ice melting into water).

High-pressure gas flow impact: Let the molten metal flow out through a small hole, and at the same time, use high-pressure inert gas (such as nitrogen or argon) to impact it like a “water gun”, breaking the metal liquid flow into small droplets. Why use inert gas? Because ordinary air would cause the metal to oxidize, while inert gas can keep the metal pure.

Rapid cooling: The small droplets cool down rapidly during flight and turn into solid powder, which is then collected.

Just like blowing soap water with a straw, the airflow breaks the soap film into many small bubbles, except here it’s metal liquid and high-pressure gas!

3. Why are gas atomized so popular?

This technology has three major advantages:

High sphericity: The powder is as round as small balls, with good fluidity, which is suitable for 3D printing.

High purity: Under the protection of inert gas, the metal will not be contaminated.

Controllable particle size: By adjusting the gas flow rate, the coarseness of the powder can be controlled.

Currently, about 40% of the metal powders used in 3D printing are prepared by gas atomization, especially high-end materials such as titanium alloys and nickel-based superalloys.

4. Challenges and the Future: Finer, Purer, Cheaper

Although gas atomization technology is powerful, it also has some issues:

High cost: Expensive equipment and large consumption of inert gas.

High energy consumption: Both melting the metal and the high-pressure gas require a lot of energy.

Scientists are researching ways to improve it, such as using ultrasonic-assisted atomization (more energy-efficient) and optimizing the gas flow design.

5. Applications in Daily Life

You might think that metal powders are far removed from daily life, but in fact, they are hidden in many high-tech products:

3D printing: Metal powders are used to “print” aircraft parts and artificial joints.

Mobile phones and computers: Some precision components are made from this kind of powder.

Medical field: For instance, the material for dental implants may come from gas-atomized powders.

Summary

Gas atomization technology is like a “metamorphosis” of metals. Through high-pressure gas and rapid cooling, it turns molten metal into uniform and fine powder. Although the process is complex, the principle is not difficult to understand – it’s just like blowing bubbles, only with metal instead of soap bubbles! In the future, with the development of technology, this technology may become more efficient and cheaper, bringing more surprises to our lives.