In the world of metallic materials, titanium alloys stand out like a shining star, attracting the attention of numerous researchers and engineers with their outstanding properties and broad application prospects. Meanwhile, the rise of additive manufacturing technology has brought new opportunities for the processing and application of titanium alloys. Titanium Alloys: The Versatile “All-Rounder” Titanium […]

In the world of metals, copper alloys are a very important and widely used type of material. Copper alloys, simply put, are alloys formed by adding other elements to copper as the base. Why add other elements? This is because although pure copper has many advantages, such as good electrical and thermal conductivity and a […]

In today’s era of rapid technological advancement, metal additive manufacturing technology is gradually entering the public eye, among which the laser cladding direct energy deposition (Directed Energy Deposition, abbreviated as DED) process is particularly attracting attention. It is like a magical metal “repairer” and “creator”, playing a unique role in the field of industrial manufacturing. […]

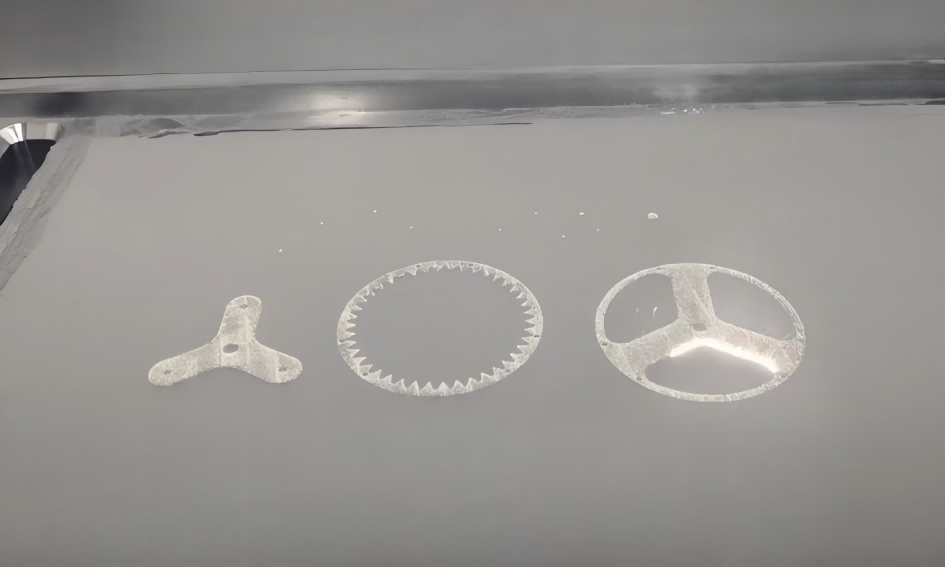

In today’s era of rapid technological advancement, 3D printing is no longer an unfamiliar term. From simple plastic trinkets to complex industrial components, 3D printing technology continues to expand our imagination. Among the various 3D printing technologies, the Laser Powder Bed Fusion (LPBF) technology for metal additive manufacturing is like a magical key, opening the […]

In modern industry and high-tech fields, the preparation of metal powders is of vital importance as it serves as the foundation for numerous advanced materials and products. Metal centrifugal atomization technology, as an efficient and high-quality method for preparing metal powders, is playing an increasingly significant role. Let’s now unveil the mystery of metal centrifugal […]

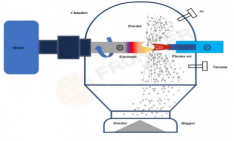

Hello everyone! Today, let’s talk about a topic that sounds very high-tech but has a really interesting principle – metal gas atomization. Imagine if you could turn a piece of metal into a pile of tiny “metal candies”. That’s the magic of gas atomization! Now, let’s use the simplest language to reveal its secrets. In […]

Did you know? Many common items in our lives, such as bicycle parts, electronic products, and even aerospace equipment, are made from metal powders! These seemingly ordinary powders actually hold many fascinating scientific secrets. Today, let’s explore the stories of oxygen, nitrogen, and impurities in metal powders and see how they act like “seasonings” to […]

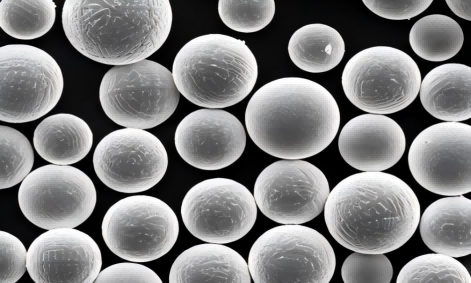

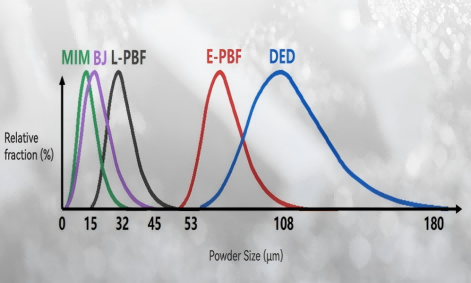

In the microscopic world of metal powder, particles aren’t all identical—they vary in size, much like grains of sand on a beach. Particle size distribution (PSD) is the key metric that describes the proportion of different-sized particles within a powder batch. It acts as a precise “ruler,” defining the collective profile of powder particles. Definition: […]

On the stage of metal powder processing—whether for 3D printing, powder metallurgy, or injection molding—the ability of powder to flow smoothly like fine sand is the first critical determinant of process success. Flowability is the key performance metric that evaluates just how easily and consistently powder can move. What is Flowability? It refers to a […]

In the world of metal powder processing—whether for 3D printing, powder metallurgy, or injection molding—how powder “piles up” directly impacts the success of subsequent processes and the performance of the final product. Apparent density (bulk density) and tap density are the two key metrics that evaluate this “stacking” ability. Apparent Density Definition: Apparent density refers […]