3D printing technology has evolved from its initial use in manufacturing plastic prototypes to the current capability of directly printing high-performance parts made of metals, ceramics, and composite materials. However, regardless of the material used, the parts freshly “out of the oven” are often only semi-finished products. To meet the design requirements for precision, strength, […]

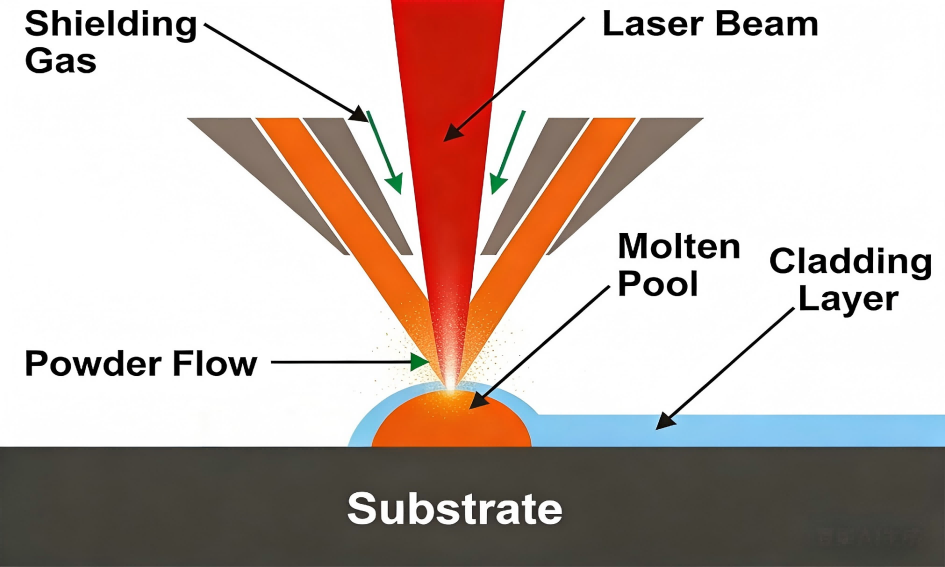

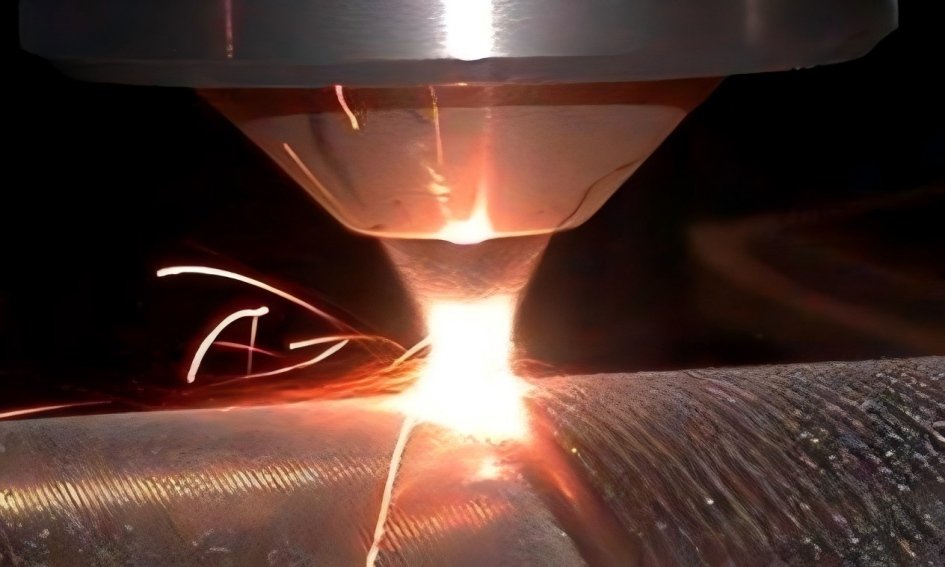

Laser cladding is an advanced surface modification technology for materials, widely used in aerospace, automotive manufacturing, mold repair, and energy equipment fields. It uses a high-energy laser beam to rapidly melt alloy powder and the substrate surface and metallurgically bond them, forming a coating layer with excellent properties such as wear resistance, corrosion resistance, and […]

Non-metal 3D printing, as an important branch of additive manufacturing technology, is increasingly penetrating our daily lives and industrial production. It differs from metal 3D printing, which uses metal powders or wires as raw materials, mainly employing non-metallic substances such as plastics, resins, ceramics, composite polymers, and even biocompatible materials to build complex three-dimensional objects […]

In the modern industrial field, we often need metal components to possess extraordinary properties, such as extremely high wear resistance, corrosion resistance, or stability in extreme environments. Traditional repair or surface treatment methods are sometimes like gluing, with limited bonding strength, or like “baking” a layer of paint on the metal under the scorching sun, […]

Laser cladding powder feeding technology is a core process in laser surface modification techniques. It achieves the preparation of metallurgically bonded cladding layers on the substrate surface by precisely controlling the interaction between the powder feeding method and laser energy. The core objective of this technology is to enhance cladding efficiency, optimize coating quality, and […]

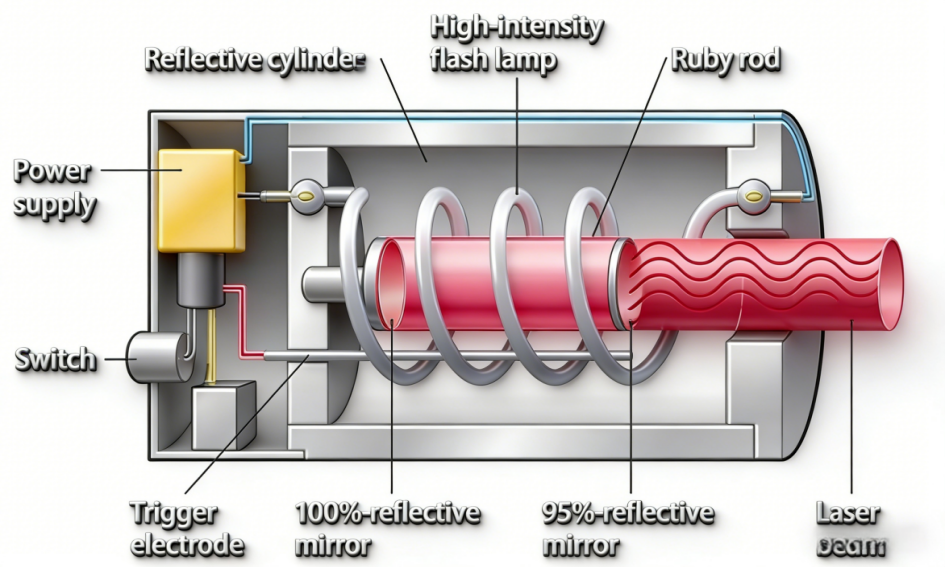

Laser technology plays a crucial role in the field of metal additive manufacturing. Its unique principles, diverse types, and remarkable characteristics drive the continuous development of metal additive manufacturing technology. (from the internet) The principle of laser generation is based on the principle of stimulated emission. In an atomic system, when an atom in a […]

Metal laser cladding is an advanced surface treatment technology that can apply a coating with special properties on the surface of metals, thereby enhancing their wear resistance, corrosion resistance, and other characteristics. To achieve a good cladding effect, it is necessary to set the process parameters reasonably. Here are several key parameters for your reference. […]

Among the vast family of metallic materials, aluminum alloys stand out as a star member. They are alloys based on aluminum with a certain amount of other alloying elements added, and are one of the light metal materials. The birth of aluminum alloy can be traced back to 1906. During an experiment, German metallurgist Wilm […]

Recently, Frontier Material successfully delivered a batch of high-quality dental nickel-chromium alloy powder and titanium alloy powder to an overseas customer, and received high praise from the customers after their use. Frontier Material has always been dedicated to the research and development and production of alloy powder for dental 3D printing. With years of technological […]

In many modern industrial fields, such as aerospace and energy power, superalloys play a crucial role. So, what exactly are superalloys? Superalloys refer to a class of metallic materials that can operate for long periods at temperatures above 600°C under certain stress conditions. They possess excellent high-temperature strength, good oxidation and thermal corrosion resistance, good […]