Analysis of Laser Technology in Metal Additive Manufacturing

Laser technology plays a crucial role in the field of metal additive manufacturing. Its unique principles, diverse types, and remarkable characteristics drive the continuous development of metal additive manufacturing technology.

(from the internet)

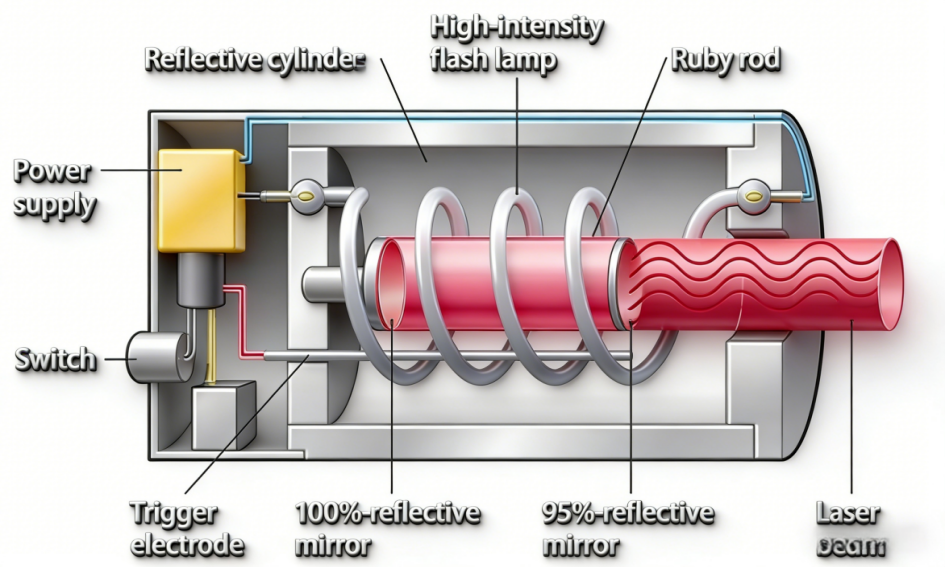

The principle of laser generation is based on the principle of stimulated emission. In an atomic system, when an atom in a high energy level is induced by a photon with energy equal to the energy difference between the two levels, it will transition to a lower energy level and produce a photon that is completely identical to the incident photon in terms of frequency, phase, propagation direction and polarization state. This is stimulated emission. By continuously exciting the atoms in the lower energy level to the higher energy level through an excitation source, a population inversion distribution is formed. Then, through the action of a resonant cavity, the photons produced by stimulated emission oscillate and amplify within the cavity, and eventually a high-energy, highly directional laser beam is output.

Types of Lasers

Classification by Working Medium

- Solid-state Lasers

Working medium: Solid materials are used as the gain medium, such as neodymium-doped yttrium aluminum garnet (Nd:YAG) crystals. In Nd:YAG crystals, neodymium ions (Nd³⁺) are the active ions that generate laser light, and yttrium aluminum garnet (YAG) serves as the matrix material, providing a suitable physical and chemical environment for the neodymium ions.

Characteristics and Applications: They have high energy and peak power, capable of releasing a large amount of energy in a short time, achieving rapid melting and solidification of metal materials. They have unique advantages in the additive manufacturing of small metal parts, especially suitable for manufacturing electronic components with high precision and surface quality requirements.

- Semiconductor Laser

Working Material: Mainly consists of PN junctions based on III-V compound semiconductor materials such as indium gallium arsenide (InGaAs). Near-infrared lasers (typically 808–980 nm) are generated directly through current injection, while emerging blue types use gallium nitride (GaN) material.

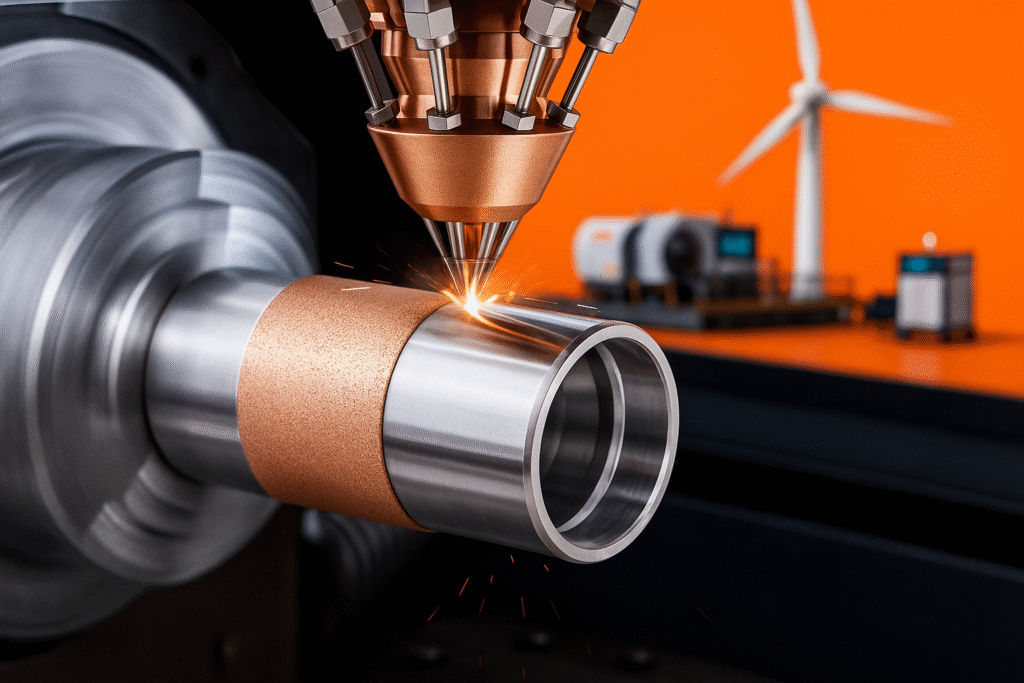

Characteristics and Applications: High electro-optical conversion efficiency (>40%), compact structure, low operating cost, and good reliability, but the beam quality is poor, making it difficult to focus into a tiny spot, which limits its application in high-precision processes. Therefore, semiconductor lasers are mainly used in laser directed energy deposition (DED) and large-area cladding scenarios where precision requirements are not high but efficiency and economics are emphasised, such as large workpiece repair, wear-resistant coating preparation, and remanufacturing. In recent years, blue semiconductor lasers have also shown potential applications in additive manufacturing of highly reflective metals such as copper and aluminium.

- Fiber Lasers

Working medium: Fiber doped with rare earth elements (such as ytterbium, erbium, thulium, etc.) is used as the gain medium. For example, in ytterbium-doped fiber lasers (YDFL), ytterbium ions in the fiber absorb the energy of the pump light, achieving population inversion and generating laser light.

Characteristics and Applications: They have good beam quality, high conversion efficiency, and good heat dissipation performance. In metal additive manufacturing, fiber lasers can achieve high-precision cladding and deposition, and are used to manufacture high-quality metal parts, such as engine blades in the aerospace field.

- Gas Lasers

Working medium: Gases or vapors are used as the gain medium, with carbon dioxide (CO₂) lasers being common. In CO₂ lasers, a mixture of CO₂ gas, nitrogen, and helium is excited to a high energy state under high-voltage discharge, generating stimulated radiation and emitting laser light.

Characteristics and Applications: They have high output power, with continuous output power reaching several kilowatts or more. However, due to the relatively low absorption rate of metals for CO₂ lasers, their application in metal additive manufacturing is relatively limited, mainly used in metal surface treatment processes with lower precision requirements.

Classification by Output Mode

- Continuous Lasers

Output Characteristics: Continuously output laser light, with relatively stable power over time. In metal additive manufacturing, continuous lasers can continuously provide energy, allowing metal materials to continuously melt and solidify, forming continuous melt tracks.

Application Scenarios: Suitable for large-area metal deposition and cladding, which can improve manufacturing efficiency. For example, in the manufacturing of large metal structural components, continuous lasers can quickly complete the material deposition process.

- Pulsed Lasers

Output Characteristics: Output laser light in pulses, with each pulse having a very high peak power and a certain time interval between pulses. The energy of pulsed lasers is concentrated in a short period of time, generating a high temperature gradient.

Application Scenarios: Suitable for manufacturing metal parts with high requirements for the heat-affected zone, such as thin-walled parts and fine-structured components. Pulsed lasers can reduce heat diffusion and minimize the thermal impact on surrounding materials, thereby improving the precision and quality of parts.

Classification by Wavelength

- Infrared Lasers

Wavelength Range: Wavelengths are typically in the near-infrared to mid-infrared region, such as 1064nm for Nd:YAG lasers, around 1070 – 1080nm for fiber lasers, and 10.6μm for CO₂ lasers.

Characteristics and Applications: Metals have a good absorption rate for infrared lasers, effectively converting laser energy into heat energy to melt metals. Therefore, infrared lasers are widely used in metal additive manufacturing and can be used for processing various metal materials, such as stainless steel, aluminum alloys, and titanium alloys.

- Visible Light Lasers

Wavelength Range: Wavelengths are in the visible light range, such as 532nm green light lasers (generated by the second harmonic of Nd:YAG lasers).

Characteristics and Applications: Some metals have a relatively high absorption rate for visible light lasers, especially high-reflectivity metals such as copper. Visible light lasers have certain advantages when processing these metals, which can improve processing efficiency and quality.

- Ultraviolet lasers

Wavelength range: The wavelength is in the ultraviolet region, generally less than 400nm. The photon energy of ultraviolet lasers is relatively high, which can directly break the chemical bonds of metal materials, achieving material removal and processing.

Characteristics and applications: In metal additive manufacturing, ultraviolet lasers are mainly used for micro-nano processing and surface treatment. For example, when manufacturing micro-electromechanical systems (MEMS) and micro-metal parts, ultraviolet lasers can achieve high-precision processing.

Characteristics of Laser

– High energy density

Laser can concentrate a large amount of energy in a very small area, rapidly raising the temperature of metal materials to their melting point or even boiling point, achieving rapid melting and forming. This significantly enhances the efficiency of additive manufacturing and enables the processing of high-melting-point metals such as titanium alloys and nickel-based alloys.

– Excellent directionality

The laser beam travels almost in a straight line with a very small divergence angle. This allows the laser to precisely focus on specific locations on the metal material, ensuring high precision and resolution in additive manufacturing and enabling the production of complex-shaped metal parts with high dimensional accuracy.

– Strong controllability

By adjusting parameters such as laser power, pulse frequency, and pulse width, the melting and solidification processes of metal materials can be precisely controlled, thereby regulating the microstructure and properties of the parts. For instance, adjusting laser parameters can improve the density, hardness, and toughness of the parts.

Laser, with its unique principle, diverse types and remarkable features, has become an indispensable key technology in metal additive manufacturing, providing strong support for the development of advanced manufacturing.