Aluminum alloys and additive manufacturing: Unveiling a new chapter in advanced materials and cutting-edge processes

Among the vast family of metallic materials, aluminum alloys stand out as a star member. They are alloys based on aluminum with a certain amount of other alloying elements added, and are one of the light metal materials.

The birth of aluminum alloy can be traced back to 1906. During an experiment, German metallurgist Wilm discovered that adding a small amount of copper and magnesium to aluminum significantly increased its hardness and strength. Through subsequent research, he determined the formula for aluminum alloy containing copper, magnesium, manganese and other elements, which was the initial aluminum alloy. Since then, aluminum alloy has stood out in many fields due to its numerous advantages.

Aluminum alloy has the characteristic of low density, being only about one-third that of steel. This makes it highly effective in the aerospace industry. The fuselage, wings and other key components of aircraft are made of aluminum alloy, which can greatly reduce the weight of the aircraft, thereby lowering fuel consumption and improving flight efficiency. At the same time, aluminum alloy also has good corrosion resistance. In a humid environment or one with a certain amount of salt, a dense oxide film forms on its surface, preventing further corrosion. Some ships that sail at sea use aluminum alloy for some of their structures, which can effectively resist the erosion of seawater and extend their service life. In addition, aluminum alloy has excellent processing performance and can be processed into various complex-shaped parts through casting, forging, extrusion and other methods, and is widely used in the automotive and electronic industries.

With the rapid development of technology, 3D printing technology has brought new changes to the application of aluminum alloy. Traditional processing methods for aluminum alloy often face complex processes and high costs when manufacturing some complex-structured and high-precision parts. However, 3D printing technology, also known as additive manufacturing, is a technology that uses digital model files as the basis and powder-like metals or plastics and other bondable materials to construct objects layer by layer.

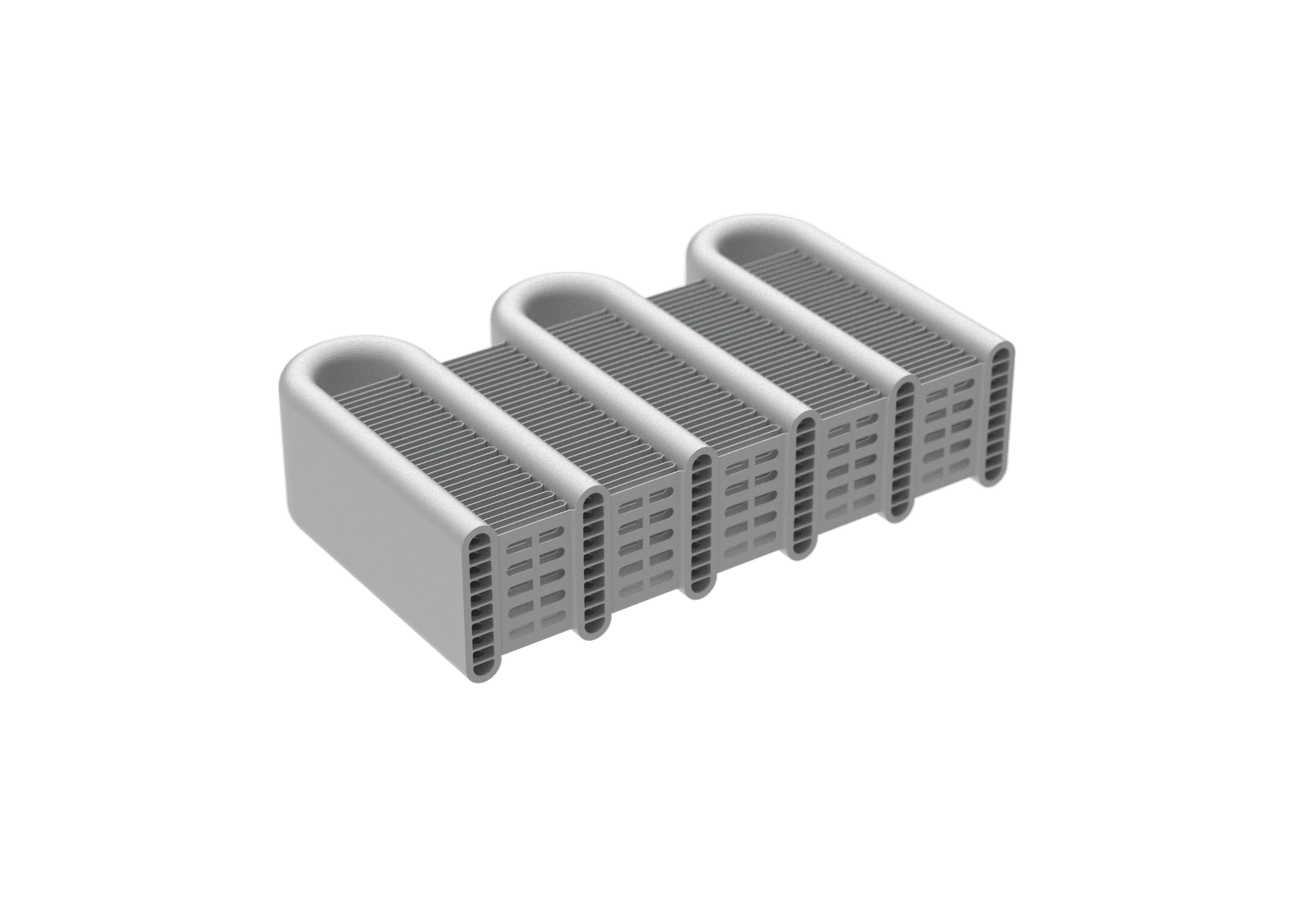

In the 3D printing of aluminum alloy, powder bed fusion technology is mainly used. On the one hand, it can achieve a high degree of design freedom and manufacture complex internal structures that are difficult to achieve with traditional processing methods, such as lattice structures and porous structures. These structures not only reduce the weight of parts but also improve their strength and rigidity. On the other hand, 3D printing can achieve customized production and quickly manufacture personalized aluminum alloy parts according to different needs, greatly shortening the product development cycle and production cycle.

At present, 3D printing of aluminum alloys has been widely applied in aerospace, medical, automotive and other fields. In the aerospace industry, aluminum alloy parts manufactured through 3D printing can meet the requirements of aircraft for lightweight and high performance; in the medical field, customized aluminum alloy implants can better fit the patient’s body structure and improve the treatment effect; in the automotive industry, 3D printed aluminum alloy parts help achieve lightweighting of vehicles and reduce energy consumption.

However, 3D printing technology of aluminum alloys also faces some challenges. For instance, defects such as pores and cracks may occur during the printing process, affecting the performance of the parts; the cost of printing materials is relatively high, which limits its large-scale application. Nevertheless, with the continuous progress of technology and in-depth research, these problems are expected to be gradually solved.

Aluminum alloys have an important position in the industrial field due to their unique properties, and the integration of 3D printing technology has injected new vitality into the development of aluminum alloys. It is believed that in the future, aluminum alloys and 3D printing technology of aluminum alloys will create unlimited possibilities in more fields.