Post-processing of 3D printed parts: The crucial step from “roughcast” to finished product

3D printing technology has evolved from its initial use in manufacturing plastic prototypes to the current capability of directly printing high-performance parts made of metals, ceramics, and composite materials. However, regardless of the material used, the parts freshly “out of the oven” are often only semi-finished products. To meet the design requirements for precision, strength, or appearance, post-processing has become an indispensable key step. Moreover, the post-processing methods for metal and non-metal (such as plastic and resin) printed parts differ significantly in principle and process.

Image from the internet

I. Post-processing of Non-metallic 3D Printed Parts

The most common non-metallic prints include FDM (Fused Deposition Modeling) plastic parts and SLA/DLP (Stereolithography/Digital Light Processing) resin parts.

- FDM Plastic Parts (such as PLA, ABS, PETG)

Removing Supports: Supports can be removed by hand or with tools, and the marks can be sanded off with sandpaper.

Polishing: Use sandpapers of different grits (80–2000 grit) to polish the surface step by step; ABS can also be polished with acetone vapor to make the surface as smooth as injection-molded parts.

Painting and Spraying: Applying primer and spray paint can significantly enhance the appearance quality, suitable for models and display items.

Heat Treatment (Annealing): For some engineering plastics (such as nylon, PC), heating can reduce internal stress and improve dimensional stability. - SLA/DLP Resin Parts

Cleaning: After printing, use isopropyl alcohol (IPA) or a dedicated cleaning solution to remove uncured resin.

Secondary UV Curing: Further curing under ultraviolet light ensures complete hardening of the material and improves mechanical properties.

Polishing and Painting: High-precision models often require fine sanding before painting, which is used in dental and jewelry casting applications.

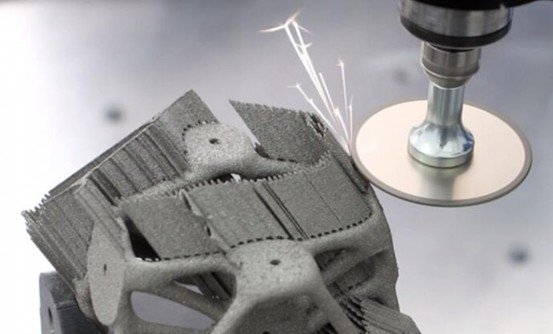

Image from the internet

II. Post-processing of Metal 3D Printed Parts

Metal 3D printing (such as SLM – Selective Laser Melting and EBM – Electron Beam Melting) is mainly used in aerospace, medical implants, molds, and other fields, where performance requirements are extremely high, and post-processing is more complex.

- Removal of Base Plate and Support Structures

Printed parts are usually welded to a metal base plate and need to be separated by wire cutting, sawing, or other methods.

Internal or complex support structures need to be carefully removed using pliers, electrical discharge, or chemical methods. - Heat Treatment

Stress relief annealing: Eliminate residual stress generated during the printing process to prevent deformation and cracking.

Solution and aging treatment: For stainless steel, titanium alloys, nickel-based superalloys, etc., to optimize microstructure and enhance strength and corrosion resistance. - Surface Treatment

Sandblasting/shot peening: Remove surface oxide layers and powder residues, and improve fatigue performance.

Machining: CNC precision machining of key mating surfaces (such as threads, bearing holes) to ensure dimensional accuracy.

Polishing and electrochemical treatment: Medical implants often require mirror polishing; some parts undergo electrolytic polishing or anodizing to enhance corrosion resistance.

Hot Isostatic Pressing (HIP): Close internal micropores under high temperature and high pressure, significantly improving density and mechanical properties, commonly used for aerospace engine components.

III. Core Objectives of Post-Processing

Whether for metals or non-metals, post-processing serves three main objectives:

Enhancing functionality: improving strength, sealing, wear resistance, etc.;

Ensuring precision and consistency: meeting assembly or engineering application requirements;

Improving appearance: transforming from a rough “blank” to a deliverable finished product.

If 3D printing is about “shaping”, then post-processing is about “soul-casting”. Metal parts aim for ultimate performance and reliability, while non-metal parts focus on efficiency and aesthetics. Although their paths differ, both jointly interpret the leap of additive manufacturing from “being printable” to “being usable well”. With the development of automated post-processing equipment, this process will become more efficient and intelligent in the future, further unleashing the industrial potential of 3D printing.