Common Defects in Laser Cladding and Their Causes

Laser cladding is an advanced surface modification technology for materials, widely used in aerospace, automotive manufacturing, mold repair, and energy equipment fields. It uses a high-energy laser beam to rapidly melt alloy powder and the substrate surface and metallurgically bond them, forming a coating layer with excellent properties such as wear resistance, corrosion resistance, and high-temperature resistance. However, despite its significant advantages, this technology still faces many challenges in practical applications, among which the defect problems of the cladding layer are one of the key factors restricting its large-scale industrial promotion. This article will introduce you to several common types of defects in the laser cladding process and their causes.

I. Porosity: The “Hidden Cavities” in Coatings

Porosity is one of the most common internal defects in laser cladding layers. These tiny holes reduce the density of the coating, weaken its mechanical properties, and serve as the starting points for crack initiation.

The main causes include:

– Insufficient or improper shielding gas: If the inert gas (such as argon) is not adequately protective during the laser cladding process, oxygen and hydrogen from the air may enter the molten pool, form bubbles upon heating, and fail to escape in time, resulting in porosity.

– Moisture or organic matter in the powder: If the alloy powder fed in contains moisture or organic components like binders, they will vaporize rapidly at high temperatures, and the vapor cannot be expelled in time, leading to porosity. – Unreasonable process parameters: For instance, if the laser power is too low or the scanning speed is too fast, the molten pool exists for a short time, and the gases do not have enough time to escape, easily getting trapped in the solidified structure.

The image is from the internet.

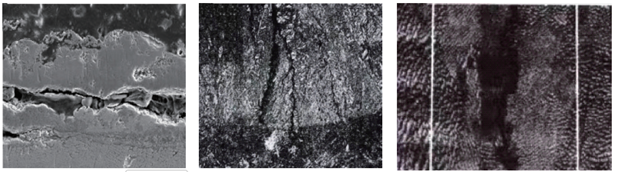

II. Cracks: The “Invisible Killer” Threatening the Integrity of Coatings

Cracks are regarded as one of the most serious problems in laser cladding, especially prominent in thick layer cladding or with high-hardness materials. Cracks often occur on the surface, at the interlayer overlap zone, or at the interface. In severe cases, they can lead to coating peeling and failure.

The main causes are as follows:

1. Excessive thermal stress: The rapid heating and cooling by the laser create a sharp temperature gradient, causing tensile stress during material contraction and leading to cracking, particularly in materials with poor toughness.

2. Mismatch in thermal physical properties: A large difference in the thermal expansion coefficients between the cladding and the substrate results in inconsistent deformation during cooling, generating significant residual stress and causing cracking.

3. Inhomogeneous microstructure and segregation: Alloy elements undergo crystallization segregation during solidification, creating local compositional inhomogeneities and stress concentration points.

4. Cracks induced by pores and inclusions: Existing defects can act as stress concentration sources, which may expand into cracks during subsequent cooling or service.

5. Stress concentration due to complex structures: In complex-shaped workpieces, uneven heat transfer can lead to the accumulation of high stress in local areas. In addition, the superposition of residual stress in the overlap areas during multi-pass cladding significantly increases the crack sensitivity.

The image is from the internet.

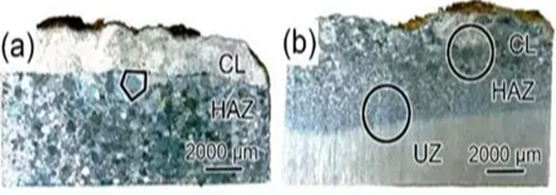

III. Surface Quality Issues: Unevenness and Peeling

The ideal cladding layer should have a smooth, continuous and dense surface. However, in reality, it often presents with roughness, wavy undulations, and even local peeling (delamination) phenomena.

Common causes include:

– Excessive wire speed or insufficient power: The cladding time is short, the powder is not fully melted, and the bonding with the substrate is poor, resulting in a decrease in bonding strength and easy peeling.

– Excessive powder feeding or overly thick coating: The internal stress in thick coatings is large, and the contraction during cooling is intense, easily causing cracks and warping, ultimately leading to delamination.

– Improper control of the laser spot diameter and overlap rate: An overly large spot or uneven overlap can cause inconsistent depths between cladding tracks, affecting the overall flatness and uniformity.

IV. Other Defects

– Excessive dilution: Excessive melting of the substrate material into the cladding layer alters the original design composition, affecting the coating performance. This is usually related to excessive laser power or too slow a scanning speed.

– Inclusions: Impurities such as powder contamination or unremoved oxide scales mix into the molten pool, forming non-metallic inclusions that disrupt the continuity of the structure.

– Lack of fusion or penetration: Insufficient energy input or asynchronous powder feeding can result in incomplete melting of the powder and poor bonding with the substrate.

How to Address These Issues? – Key Directions for Quality Control

To reduce the aforementioned defects, researchers and engineers have proposed various effective strategies:

– Optimize process parameters: Reasonably match laser power, scanning speed, spot diameter, and powder feeding rate, and use “specific energy” (Es = P/DV) to comprehensively control energy input.

– Preheating and post-heating treatment: By heating the substrate to reduce temperature differences and minimize thermal stress, cracks can be significantly suppressed.

– Improve material design: Select alloy powders with thermal expansion coefficients matching the substrate and add trace elements to improve wettability.

– Application of auxiliary technologies: For instance, electromagnetic stirring can refine grains, homogenize the structure, and reduce segregation and porosity.

– New high-speed laser cladding technologies: Utilize coaxial powder feeding and ultra-high-speed scanning to reduce heat input, enhance efficiency, and improve surface quality.

Conclusion Laser cladding technology, with its high precision, low dilution rate and excellent metallurgical bonding performance, is gradually becoming a core means in high-end manufacturing and remanufacturing. Although defect issues still exist, with the deepening of process understanding and technological progress, these problems are being overcome one by one. In the future, with the development of intelligent control, online monitoring and new material systems, laser cladding will surely move towards a new stage of higher quality and higher efficiency, injecting strong impetus into the transformation and upgrading of the manufacturing industry