Non-metal 3D Printing: The Soft Power Shaping the Future

Non-metal 3D printing, as an important branch of additive manufacturing technology, is increasingly penetrating our daily lives and industrial production. It differs from metal 3D printing, which uses metal powders or wires as raw materials, mainly employing non-metallic substances such as plastics, resins, ceramics, composite polymers, and even biocompatible materials to build complex three-dimensional objects layer by layer. This technology not only lowers the manufacturing threshold but also greatly expands design freedom, becoming a key force driving personalized customization, rapid prototyping, and small-batch production.

The Four Major Schools, Each Displaying Their Unique Skills

1. Fused Filament Fabrication (FFF/FDM) – The “Hot Glue Gun” School

Representative Materials: PLA, PETG, TPU, Carbon Fiber Reinforced PA

Principle: Filament is heated to a semi-molten state and stacked layer by layer like cake decorating.

Highlights: Equipment can be purchased for just a few thousand yuan and used in the office; water-soluble supports allow for “suspended” structures.

Pain Points: Obvious layer lines; Z-direction strength is only 30%–50% of XY-direction strength.

2. Stereolithography (SLA/DLP/LCD) – The “Ultraviolet Engraving” School

Representative Materials: Acrylate Resin, Epoxy-Modified Resin

Principle: Ultraviolet light “cures” liquid monomers into solids, with a resolution of up to 0.05 mm and a surface finish comparable to direct polishing.

Highlights: Dental aligners, anime prototypes, jewelry lost-wax casting molds, 24-hour delivery.

Pain Points: Most resins are brittle and may yellow under long-term sunlight; uncured liquid must be stored in the dark and recycled.

3. Powder Bed Fusion (SLS/MJF) – The “Laser Selective Sintering” School

Representative Materials: Nylon 12, TPU, Polystyrene (for investment casting)

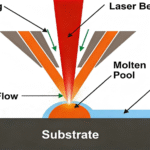

Principle: CO₂ laser or heated ink “welds” powder particles together, with surrounding powder serving as support.

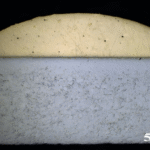

Highlights: No need for support structures; complex lattices, integral hinges, and moving gears can be produced in one go; nylon parts have strength comparable to injection molding.

Pain Points: Equipment costs millions; powder requires constant temperature and humidity control; powder cleaning is like a small sandstorm.

4. Jet/Binding (MJF, Binder Jetting) – The “Color Ink” School

Representative Materials: Gypsum, Ceramic Powder, Quartz Sand

Principle: The print head first sprays a micro-droplet of adhesive, then color ink, and finally cures and impregnates with wax for reinforcement.

Highlights: Full-color 24-bit color, geological sand tables, architectural models, and cultural and creative blind boxes are “what you see is what you get”.

Pain Points: Fragile parts, water-sensitive, need to be wax- or glue-impregnated to extend lifespan.

The Evolution of Materials: From “Toy Plastic” to “Aerospace Ceramics”

Before 2020: PLA could only be used for “prototypes” and would soften at 60°C.

2022: BASF introduced Ultrafuse® PA6 CF, containing 20% short carbon fibers, with a strength of 100 MPa, replacing small aluminum alloy brackets.

2024: Tethon in the United States launched SiC ceramic resin, which is sintered after light curing, with a density of 99%, and has been used in hypersonic wind tunnel models.

2026 Prediction: Recyclable bio-based resins enter dentistry, creating a closed loop of print-recycle-reprint, reducing carbon footprint by 70%

The application fields are extensive.

The application fields of non-metallic additive manufacturing are extremely extensive. In the aerospace industry, it can produce lightweight and high-strength aviation components, reducing the weight of aircraft and improving fuel efficiency. In the construction industry, 3D printing technology can be used to quickly make architectural models, helping designers to more intuitively display design plans, and even directly print some building components. In the field of culture and art, artists can use additive manufacturing technology to turn their creativity into reality and create unique sculptures.

Challenges Faced and Future Prospects Although non-metallic additive manufacturing has many advantages, it also faces some challenges. For instance, the performance of materials still needs to be further improved to meet more demanding usage requirements; the printing speed is relatively slow, which limits the efficiency of large-scale production; and the cost of equipment and materials is relatively high, hindering its wider application. However, with the continuous advancement of technology, these problems are gradually being solved. In the future, non-metallic additive manufacturing is expected to be applied in more fields, promoting the development of manufacturing towards intelligence, personalization, and greenness, and bringing more surprises and changes to our lives.