Ultra-high-speed laser cladding: The black technology that gives metals “superhero armor”

In the modern industrial field, we often need metal components to possess extraordinary properties, such as extremely high wear resistance, corrosion resistance, or stability in extreme environments. Traditional repair or surface treatment methods are sometimes like gluing, with limited bonding strength, or like “baking” a layer of paint on the metal under the scorching sun, which is prone to deformation and peeling.

At this time, a technology called “Extreme High-Speed Laser Material Deposition (EHLA)” emerged, which is hailed as the “shining star” in the field of metal surface treatment and is revolutionizing our understanding of metal repair and strengthening.

What is ultra-high-speed laser cladding?

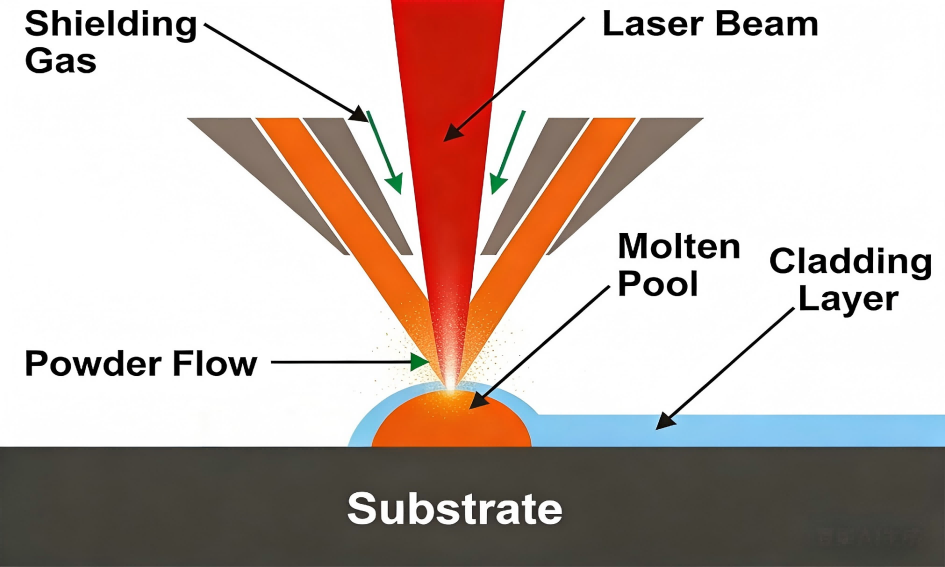

In simple terms, laser cladding uses a high-energy laser beam as a “super glue” to instantly melt a special alloy powder (or wire) and the surface of a metal substrate, and then quickly solidify it to form a high-performance coating that achieves atomic-level bonding with the substrate. “Ultra-high-speed” laser cladding is an “upgraded” or “extreme” version of this technology.

Where does its “ultra-high speed” lie?

Compared with traditional laser cladding, the most significant difference of ultra-high-speed laser cladding lies in speed and energy utilization.

● Astonishing speed: The line speed of traditional laser cladding is usually 0.6-1 meters per minute, while ultra-high-speed laser cladding can reach 20-200 meters per minute, increasing efficiency by tens or even hundreds of times. This means that a repair job that used to take several hours can now be completed in just a few minutes.

● “Dual energy utilization”: In traditional processes, the laser mainly heats the substrate to form a molten pool, and the powder melts after falling into the molten pool. In the ultra-high-speed process, the laser beam is precisely designed so that part of the energy directly preheats and melts the powder flow, while the other part heats the substrate. The powder is already in a molten or semi-molten state before contacting the substrate, significantly shortening the interaction time with the substrate.

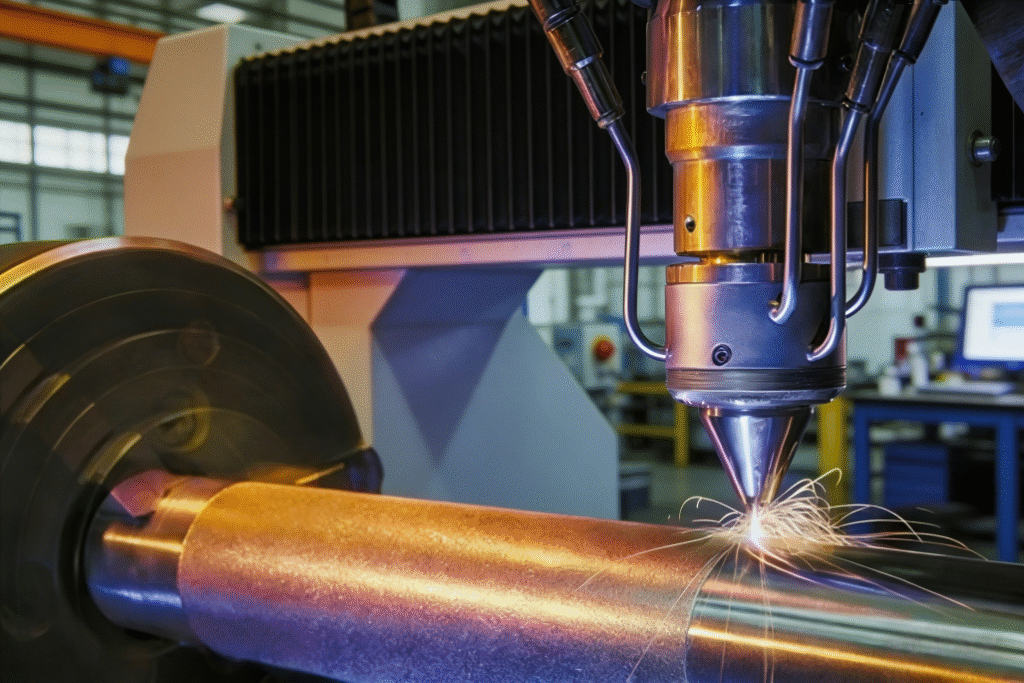

The picture is from the Internet.

The “Magical Effects” Brought by Ultra-High Speed

This “fast” is not merely about efficiency improvement, but also leads to a leap in coating quality:

- “Cold” processing feature: Due to the extremely short interaction time between the laser and the material (millisecond level), heat has no time to conduct deeply into the substrate, resulting in a very small heat-affected zone and almost no deformation of the workpiece. This is crucial for the repair of precision components.

- Thinner and denser coating: Ultra-high speed cladding can produce extremely thin coatings with a thickness of 20-100 microns, and the structure is very fine and dense with an extremely low porosity. This makes the coating harder, with much better wear resistance and corrosion resistance than traditional coatings.

- Extremely low dilution rate: The “dilution rate” refers to the proportion of base material mixed into the coating. The dilution rate of ultra-high speed cladding is usually less than 5%, meaning the coating can better maintain its original excellent properties and will not be “contaminated” by the base material.

- High material utilization rate: The powder collection efficiency can reach over 99%, and almost all the powder can be effectively utilized, reducing waste.

Where can it be used?

The application prospects of this technology are very broad:

● Industrial repair: For example, hydraulic support columns in coal mining, oil drill pipes, train wheels, etc., which are prone to wear in harsh environments. Ultra-high-speed laser cladding can “dress” them in wear-resistant and corrosion-resistant “armor”, extending their service life by 3 to 5 times.

● Aerospace: Critical components such as engine blades and turbine discs have extremely high requirements. This technology can be used to manufacture or repair these high-performance components.

● Green manufacturing: It can replace the traditional hard chromium plating process, which not only pollutes the environment but also has far inferior coating performance compared to laser cladding. Ultra-high-speed laser cladding is a clean and environmentally friendly surface treatment technology.

In conclusion, the ultra-high-speed laser cladding technology, with its features of high efficiency, precision, quality and environmental friendliness, is becoming a powerful tool for the transformation and upgrading of modern manufacturing. It not only rejuvenates old metal parts but also provides strong technical support for the high-end equipment manufacturing industry, making it a well-deserved “industrial beautician” and “metal guardian”.