Introduction to Laser Cladding Powder Feeding Technology

Laser cladding powder feeding technology is a core process in laser surface modification techniques. It achieves the preparation of metallurgically bonded cladding layers on the substrate surface by precisely controlling the interaction between the powder feeding method and laser energy. The core objective of this technology is to enhance cladding efficiency, optimize coating quality, and reduce production costs. Its development has undergone multiple technological iterations, from the traditional pre-placement method to synchronous powder feeding, and then to ultra-high-speed central powder feeding.

The images are from the internet.

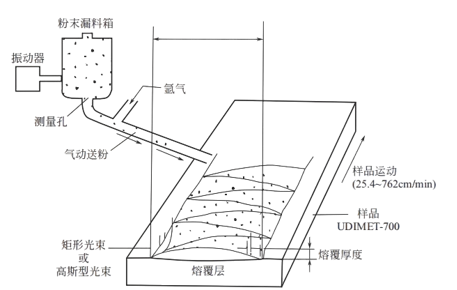

The pre-placed powder technology process uses brushing or thermal spraying to pre-apply an alloy powder layer on the substrate surface, which is then melted by laser scanning. Although this method can achieve a uniform coating thickness, it has limitations such as low powder utilization rate (usually less than 60%), inability to adjust process parameters in real time, and difficulty in handling complex curved surfaces. Currently, the pre-placed method is mainly used in laboratory research or in repair scenarios where surface flatness requirements are not high.

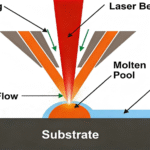

The breakthrough progress of the synchronous powder feeding technology has brought about process innovation, which can be further classified into three categories: lateral powder feeding, coaxial powder feeding, and central powder feeding. The lateral powder feeding system has a simple structure, with the powder flow and laser beam transported at an angle, suitable for the planar repair of shaft parts. However, this method has problems such as large powder ejection loss and insufficient protection of the molten pool, leading to severe oxidation, with a powder utilization rate of only about 70%. The coaxial powder feeding technology outputs the powder flow and laser beam coaxially, forming a “powder wrapped light” structure through a ring or multi-hole nozzle, allowing the powder to be evenly distributed around the laser beam. This method can achieve cladding along any path in three-dimensional space, and with inert gas protection, the powder utilization rate can be increased to over 80%, making it particularly suitable for the repair of complex curved surface components in the aerospace field.

The recently developed central powder feeding technology (light wrapped powder) marks the maturity of the third-generation powder feeding technology. This technology adopts an innovative design of a central powder channel and multiple laser beams surrounding the periphery. The metal powder flow is preheated to a semi-molten state by the ring laser beam and precisely falls into the molten pool. Compared with traditional methods, central powder feeding has four major breakthroughs: the powder utilization rate exceeds 90%; the laser energy absorption rate increases by more than 30%; the cladding efficiency reaches 0.7-1.2 square meters per hour; the molten pool existence time is shortened to the millisecond level, resulting in a dilution rate of less than 5%. These characteristics make it stand out in the field of ultra-high-speed laser cladding and have been successfully applied in scenarios such as the coating of new energy vehicle battery casings and long-term corrosion protection of hydraulic columns in precision manufacturing.

The picture is from the Internet. Current technical challenges are focused on process stability under extreme conditions. For instance, in five-axis simultaneous machining, changes in the direction of gravity can cause disturbances in the powder flow state; when cladding the inner holes with large curvature, the convergence characteristics of the powder flow are easily affected by centrifugal force. Future development directions will concentrate on multi-physics field coupling modeling, the development of intelligent closed-loop control systems, and the research on the conveying mechanism of nanostructured powders, promoting the extension of laser cladding technology into the micro-nano scale manufacturing field