Introduction to Process Parameters of Metal Laser Cladding

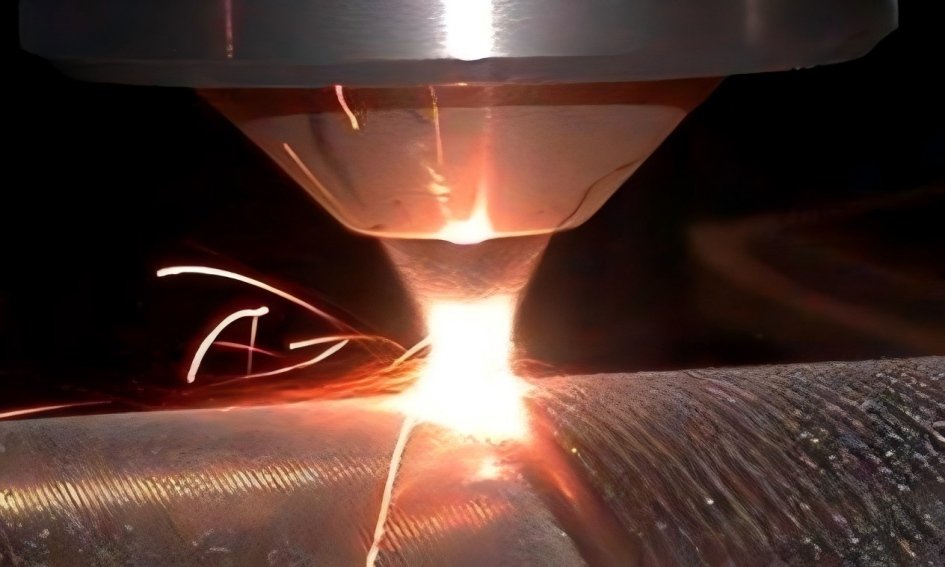

Metal laser cladding is an advanced surface treatment technology that can apply a coating with special properties on the surface of metals, thereby enhancing their wear resistance, corrosion resistance, and other characteristics. To achieve a good cladding effect, it is necessary to set the process parameters reasonably. Here are several key parameters for your reference.

Laser power

Laser power is a very important parameter in metal laser cladding. To put it simply, laser power is like the heat when cooking. If the power is too low, it is like having too small a fire, and the cladding material cannot be fully melted, resulting in poor bonding between the coating and the base metal, and problems such as peeling and detachment may occur. However, if the power is too high, it is like having too big a fire, which may burn through the cladding layer and cause the base metal to deform due to excessive heat, affecting the quality of the entire workpiece. Therefore, in actual operation, the appropriate laser power should be selected based on the characteristics of the cladding material, the size and shape of the workpiece, and other factors.

Scanning speed

Scanning speed refers to the speed at which the laser beam moves across the surface of the workpiece. It is interrelated with laser power. If the scanning speed is too fast, the laser beam stays at each position for a short time, and the cladding material cannot be fully melted, resulting in an uneven cladding layer with defects such as pores. Conversely, if the scanning speed is too slow, the laser stays in one place for too long, causing the base metal to absorb excessive heat and deform, and also wasting time and energy. Generally, through multiple trials, a scanning speed that can ensure cladding quality and improve work efficiency should be found.

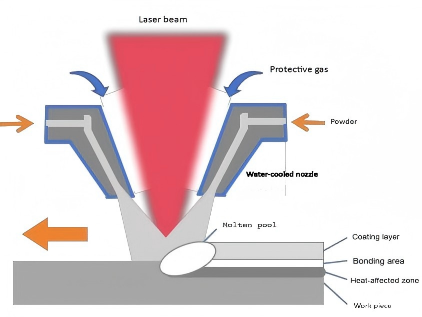

Powder feeding rate

The powder feeding rate refers to the speed at which powder of cladding material is sent into the molten pool. If the powder feeding rate is not appropriate, it will also affect the cladding effect. If the powder feeding rate is too fast, there will be too much cladding material, and the laser may not be able to melt all of it. Unmelted powder will remain on the surface of the cladding layer, making it uneven. If the powder feeding rate is too slow, the cladding layer will be very thin and cannot meet the expected performance requirements. Therefore, the powder feeding rate should be adjusted according to the laser power and scanning speed to ensure that the cladding material is evenly distributed in the molten pool and form a high-quality cladding layer.

Spot diameter

The spot diameter is the size of the circular area on the workpiece surface illuminated by the laser beam. A larger spot diameter means a larger area cladded in one pass, resulting in higher work efficiency, but the cladding depth may become shallower. A smaller spot diameter increases the cladding depth but reduces work efficiency. When choosing the spot diameter, the specific requirements of the workpiece should be considered. If the depth of the cladding layer is not a high priority and a large area needs to be cladded quickly, a larger spot diameter can be selected; if the depth and precision of the cladding layer are highly required, a smaller spot diameter should be chosen.

These parameters in the metal laser cladding process interact and restrict each other. In practical applications, the best parameter combination should be found through continuous experimentation and adjustment based on the specific workpiece and cladding requirements. Only in this way can a high-quality cladding layer be obtained and the advantages of metal laser cladding technology be fully utilized.