- Home

- portfolio

- APPLICATION

- From Fossil to Fusion: Alloy Powder Innovations Across Energy Technologies

From Fossil to Fusion: Alloy Powder Innovations Across Energy Technologies

Revolutionizing Aerospace with Alloy Powders

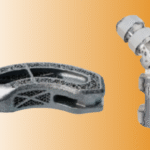

3D-printed alloys are transforming energy systems by enabling high-performance, corrosion-resistant components optimized for extreme environments. Using nickel superalloys (Inconel 718/625), titanium, and specialty steels processed via laser powder bed fusion (LPBF), key applications include:

- Nuclear reactor parts (fuel assembly cladding, control rod mechanisms with radiation resistance)

- Turbine blades and combustors for power plants (withstanding >1,000°C temperatures)

- Compact heat exchangers with intricate internal channels (40% more efficient thermal transfer)

- Corrosion-resistant valves/pipes for oil/gas extraction

- Lightweight hydrogen electrolyzer cells with catalytic surface structures. These additive-manufactured solutions enhance durability, reduce downtime through rapid part replacement, and enable complex geometries that boost efficiency in renewables (wind turbine generators), fossil fuels, and next-gen energy systems.

What are the applications of alloy powders in energy?

Alloy powders play a crucial role in energy applications by facilitating the development of advanced materials with tailored properties for various energy conversion and storage systems, including fuel cells, batteries, and solar panels.

- Fuel Cells

- Battery & Energy Storage

- Renewable Energy Equipment

- Nuclear Energy

- Thermal Management & Corrosion Protection

- Gas Turbines & Power Generation

- Solar Thermal & Concentrated Solar Power

- Hydrogen Energy

Frontier material’s metal powders deliver transformative advantages across the entire energy landscape by leveraging their exceptionally high purity, meticulously engineered spherical morphology, and optimized particle size distribution, which collectively ensure superior flowability, packing density, and printability for advanced manufacturing processes like Selective Laser Melting (SLM) or Electron Beam Melting (EBM), enabling the production of critical components—such as lightweight aluminum battery casings for electric vehicles, high-conductivity nickel-based electrodes for solid-state batteries, platinum-cobalt catalysts for fuel cell stacks, and ultra-strong aluminum alloy frames for solar panels—with unparalleled structural integrity, minimal internal porosity, and dimensional precision that significantly enhance energy conversion efficiency, power density, and operational longevity.